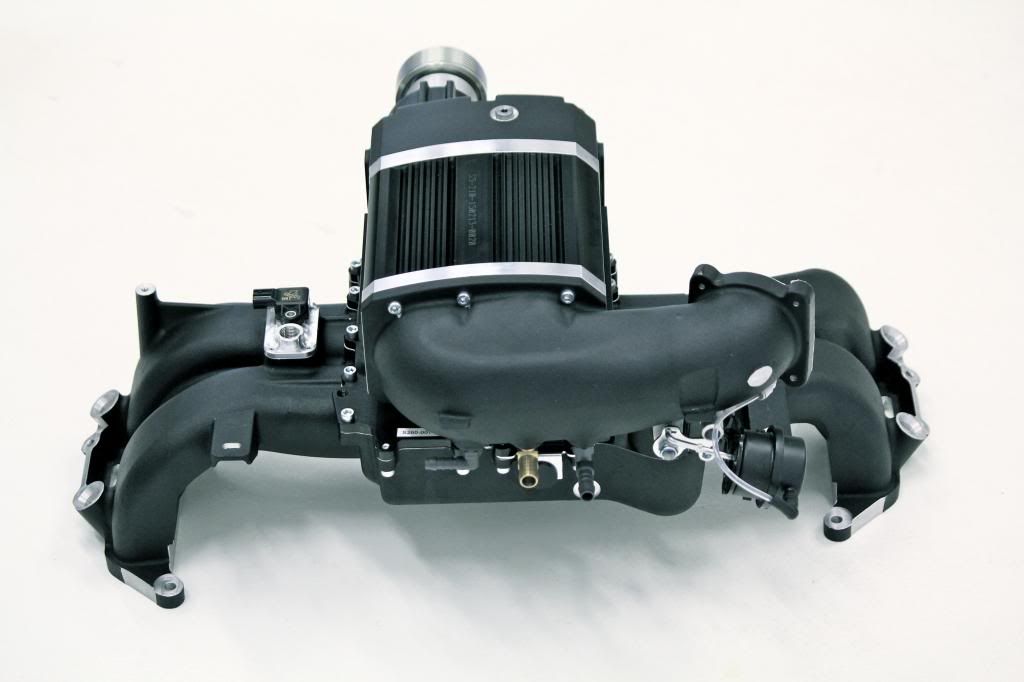

Well, to start off the unit is definitely well built. The power delivery is instant it seems like and pull steadily throughout the rpm range. As far as the down sides. The main issues we have encountered have been related to lack of intercooler, which really hurts those not blessed with 93 octane fuel in their area. This also limits current power limits because of the blower becoming a heat pump when increasing boost levels.

With these issues being a easily solvable nuisance, we decided to spend a bit more time on the back end testing tuning and developing some products for the charger over the last few weeks. What we came up for a few components to reliable increase power and a few more coming down the line as well.

Our first piece was made to properly relocate the Air Temp sensor reading to post blower to accurately read the actual charge temps entering the combustion chamber. This aides to minimize tip-knock which has plagued some many owners and tuners. Even though you can try to tune around it its not completely eliminated for those on lower grade fuel or those in higher ambient temp areas. We were given the opportunity to travel to Phoenix, AZ last week to actually test out some of our new tunes for those running 91 octane and high ambient temps. We actually were able to accurately measure power drop based on ambient inlet temp along with Knock correction applied in this extreme environment. Testing on the dyno with the hood open on the dyno vs closed actually equated out to a drop in power to the wheels of about 9-10whp. This more accurately duplicated the actual inlet temps seen on the road. This was verified by looking at previous logs of each car on the road where inlet temps were seen ranging between 48-60 degree Celsius. This also saw the ecu drastically fight to prevent tip in knock and maintain response with small but aggressive application of the throttle.

Some have solved these issues by adding either water methanol injection or running E85 or a blend of either. What we found is that relocating the charge temp sensor to after the blow properly allows for enrichment and timing adjustments to properly and accurately be applied by the ecu once charge temps begin to rise. i dont know about you guys but my hood is closed when i drive around.

| This image has been resized. Click this bar to view the full image. The original image is sized 1024x682 and weights 76KB. |

| This image has been resized. Click this bar to view the full image. The original image is sized 1024x682 and weights 53KB. |

| This image has been resized. Click this bar to view the full image. The original image is sized 1024x907 and weights 70KB. |

| This image has been resized. Click this bar to view the full image. The original image is sized 1024x682 and weights 50KB. |

| This image has been resized. Click this bar to view the full image. The original image is sized 1024x682 and weights 66KB. |

Next up for testing are a few different pulley sizes we have recently released.With the quest for additional power first thing to come is a smaller pulley. We have already released the 70mm unit earlier last week. Next up is our more extreme pushhhhhh 66mm pulley. Our first test will be of the 70mm on both pump gas non intercooled and yes INTERCOOLED. And no, this will not be down the line this will be within the week if all goes to planning. We will finish up the testing of the pulleys with E85 and WMIif we can find a kit to borrow

| This image has been resized. Click this bar to view the full image. The original image is sized 1024x682 and weights 67KB. |

| This image has been resized. Click this bar to view the full image. The original image is sized 1024x682 and weights 49KB. |

| This image has been resized. Click this bar to view the full image. The original image is sized 1024x682 and weights 42KB. |

| This image has been resized. Click this bar to view the full image. The original image is sized 1024x682 and weights 46KB. |

__________________

No comments:

Post a Comment